Pick by Light

Less mistakes, faster picking. Save money and paper with the smart ekko cloud platform for intralogistics.

In action at a large automotive group

Before:

Before ekko, many processes were primarily manual and therefore prone to errors. The picking, searching and gripping processes in particular were time-consuming and prone to errors, as they had to be acknowledged manually. As shown in the video, ekko has digitized and automated these processes.

With ekko:

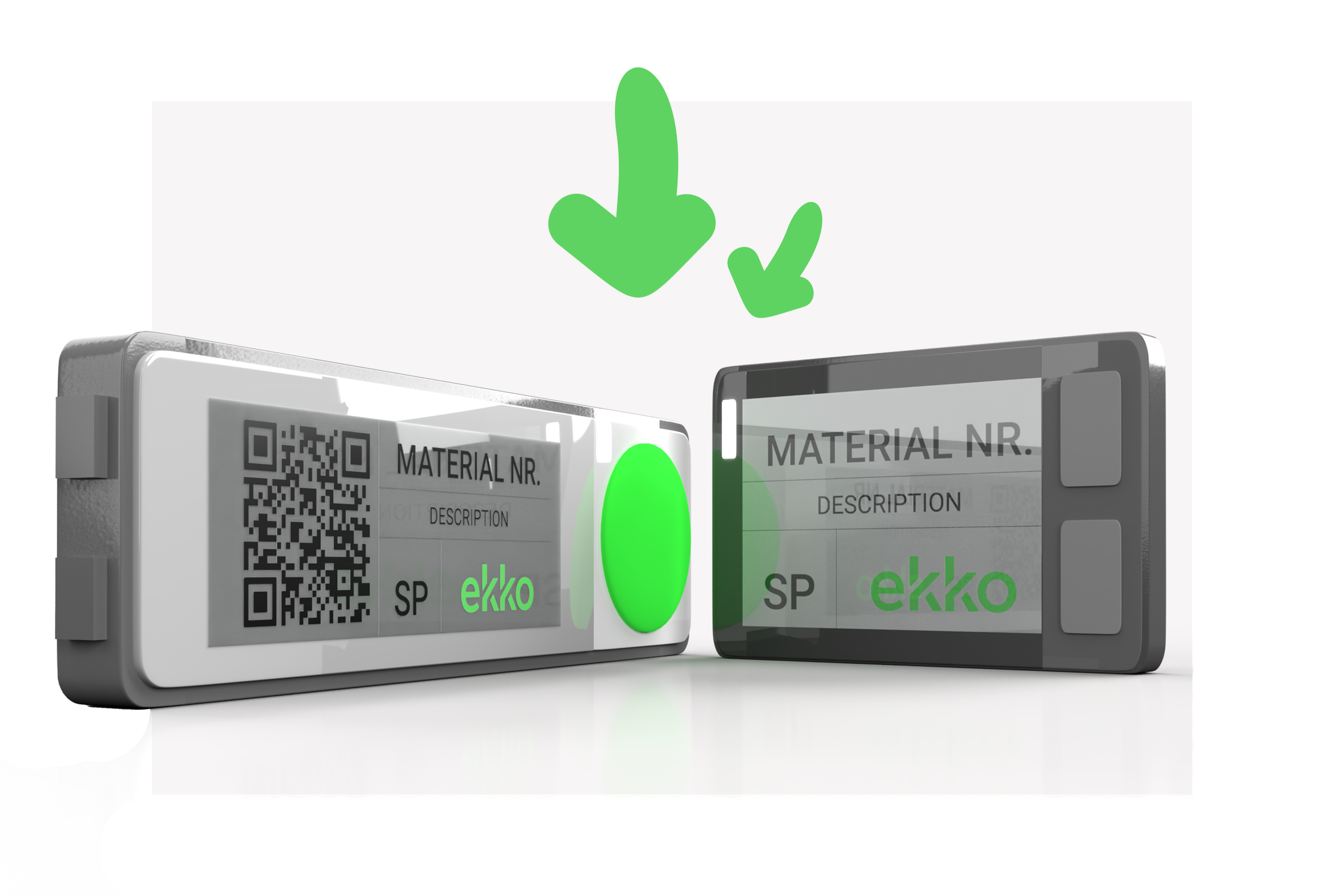

ekko has reduced this susceptibility to error by digitizing manual processes using the ekko platform, ePaper displays and scanning gloves. Pick by Light from ekko has enabled the company to achieve significant time and cost savings, while helping to reduce CO2 emissions.

How much can you specifically save?

How many picking jobs do you have per day?

That’s what you save with ekko in just one year:

Pick By Light rethought – with ekko

Example 1: Commissioning

The Problem:

In the picking areas, missing picks or fills can vary in cost – depending on the material and the time at which the error is noticed. Picking is one of the most expensive and at the same time most time-consuming work steps in the field of intralogistics.

ekko Solution:

The picking areas were equipped with ePaper displays, which are controlled by ekko according to the current order. The LED starts to light up at the correct compartment and goes out again after acknowledgement. This applies to both the filling side and the removal side on the shelf. Compared to paper, the error rate has been halved and efficiency increased.

Example 2: Order-related picking

The Problem:

Finding parts for an order takes up to several minutes because there are different, unsorted storage locations. The order number must be searched for and identified individually.

ekko Solution:

With ekko Finder, the previously digitally created copies of the order information can now be found directly by scanning the code from the order slip via MDE. All items associated with the order now light up so they can be found in seconds. The time saved sets the stage for a larger volume of processing in the future.